Open Range Group LLC, 109 E 17th St, Ste 5544,

Cheyenne, WY 82001

Open Range Group LLC, 109 E 17th St, Ste 5544, Cheyenne, WY 82001

Vulcan Technology – How It Works

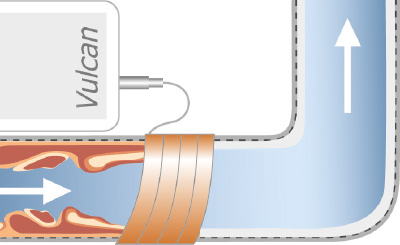

Vulcan is a physical water treatment system that does NOT use chemicals or salt. It does not change the chemical composition of the water. Instead, it changes the physical characteristics of the scale crystals in a way that the scale particles lose their adhesive power. Vulcan does not need to have direct contact with the water and sits outside of the pipe.

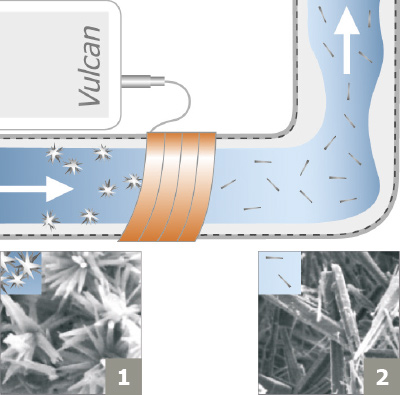

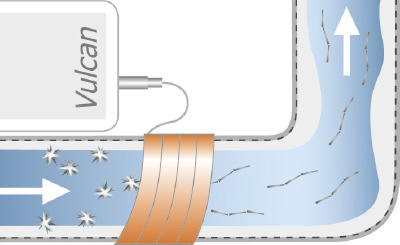

It treats the water with electric impulses which are generated in the electronic unit and are controlled by a computerized micro-chip. The signal-frequencies are transmitted via the Vulcan-impulse-bands that are wrapped around the pipe. The bands interact as pairs and form a frequency-field that changes the crystals in the water as it flows by.

Scale causes many problems

- Blocked piping systems

- Dull surfaces and malfunctioning machinery

- High costs for heating

- High expenses for cleaning

- Rust accumulation in the pipe that leads to corrosion

- Bacterial growth in drinking water carrying pipes

- Decrease in productivity

- and many more …

How does Vulcan help to solve these problems?

1. Vulcan reduces scaling in pipes and appliances

Without the Vulcan water treatment, the scale particles in the water form sticky crystals that then build solid deposits. The patented Vulcan-Impulse-Technology modifies the crystallization of calcium and magnesium using the natural process of electrophoresis. The crystals become smoother and rod-shaped and can no longer attach to each other. Scale is now washed away in the water as a fine powder. The formation of new deposits is stopped. The more rod-shaped crystals that are created, the stronger the positive effect of scale-prevention.

Mono crystals as a result of the Vulcan water treatment

When mono-crystals are created by the impulse variation, it is important that they grow as long as possible before they start their way through the piping system. The larger the crystals, the longer it takes until the crystals fall apart again and eventually “die”. In warm water, these crystals grow faster and therefore are stronger and live longer. This explains why the Vulcan-effect lasts the longest in warm water (up to seven days) and shorter in cold water (approx. two days).

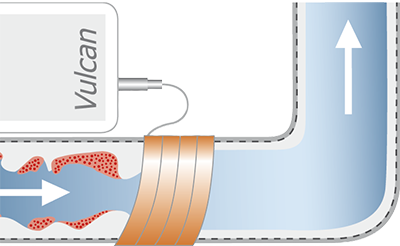

2. Vulcan gently sanitizes the piping system

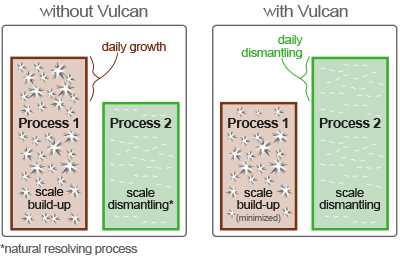

Two simultaneous processes take place in untreated, hard water:

a. In the first process, scale deposits result from calcium crystals adhering to each other which then adhere to surfaces. This first process produces carbonic acid (H2CO3) as a side product.

b. During a second process, the carbonic acid simultaneously breaks down the existing scale deposits. This is referred to as the “natural resolving process”. Because the build-up process takes place much faster than the natural resolving process the pipes’ diameter constantly decreases.

| Ca(HCO3)2 | + | Vulcan | -> | CaCo3 | + | CO2 | + | H2O |

|---|---|---|---|---|---|---|---|---|

| calcium-hydrogen-carbonate | Vulcan impulse | Mono-crystal | carbon-dioxide | water |

The Vulcan water treatment changes the balance between the scaling process and natural resolving process. The mono crystals can no longer form deposits, therefore the scale build-up of the first process is reduced. The natural scale-resolving-process now needs only to deal with existing deposits and can effectively combat them. Thus scale is removed faster than it forms. The natural surplus of carbonic acid dissolves the scale from the scale. Gradually and carefully, the deposits in the pipes will be removed.

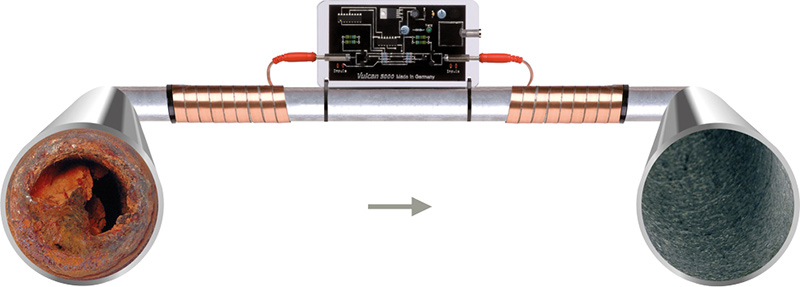

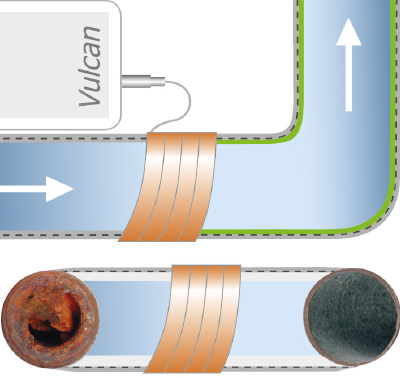

The reduction of scale = the reduction of rust

As soon as scale deposits have built up, iron particles imbed into it. Thus, the scale and the rust blend into one material that are seen as red-colored deposits in the pipe. When the Vulcan treatment dismantles the scale, it simultaneously reduces also rust with it.

Clearing out the deposits is a gentle process where scale is brought back into solution and washed out in the water as: calcium, magnesium and iron. It is absolutely save to drink as these are all healthy minerals.

The reduction of scale = the reduction of bacteria

We know that scale acts as a breeding ground for bacteria and other unwanted substances. As soon as Vulcan is installed and the scale is reduced, the bacteria breeding ground is also reduced. This way, bacterial contamination is greatly reduced or even fully removed.

3. Vulcan protects against rust damage and perforation

Copper and/or iron oxidation occurs in all metal pipes through contact with calciferous (hard) water. These oxides seriously affect the pipe surfaces and may lead to corrosion.

The Vulcan-impulse-technology generates an electrophoresis-effect which produces a protective metal-carbonate layer. According to the material of the pipe, this layer consists of copper-carbonate, iron-carbonate or zinc-carbonate and settles on all shiny metal surfaces. It protects the pipe from aggressive substances which could lead to corrosion.

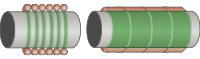

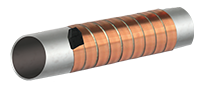

The Vulcan Impulse Bands

Vulcan operates with customized isolated copper impulse bands that are designed to firmly connect to the pipe. They are extremely thin and flexible with minimized isolation. This way, they achieve minimal spacing loss and maximize the direct-contact-ratio to 97.5%. Their special copper material with a high alloy purity degree guarantees the best possible transfer output. The copper treatment bands are a crucial factor to the performance of the water treatment.

The pipe diameter/treatment area ratio

The impulse bands cover the surface area that is vital for the treatment. The surface of the pipe that is covered by the impulse band is the “treatment area”. This area needs to be large enough to ensure that the impulses are transmitted through the pipe.

Treatment with standard cables vs. Vulcan impulse band

other cables

Vulcan impulse bands

Treatment area

Comparison:

The Vulcan Impulse Bands accumulate more direct contact compared to round cables as there is less spacing. The direct contact ratio reaches 97,5%.